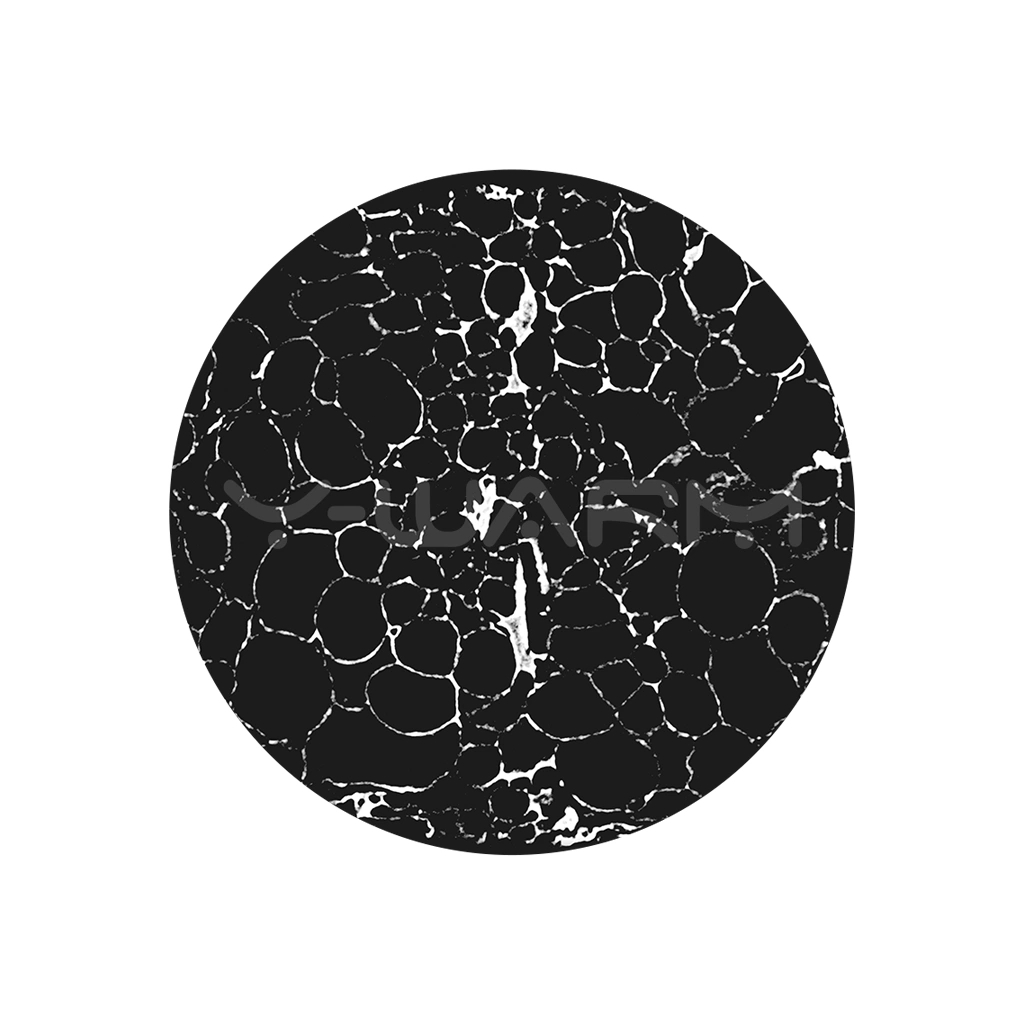

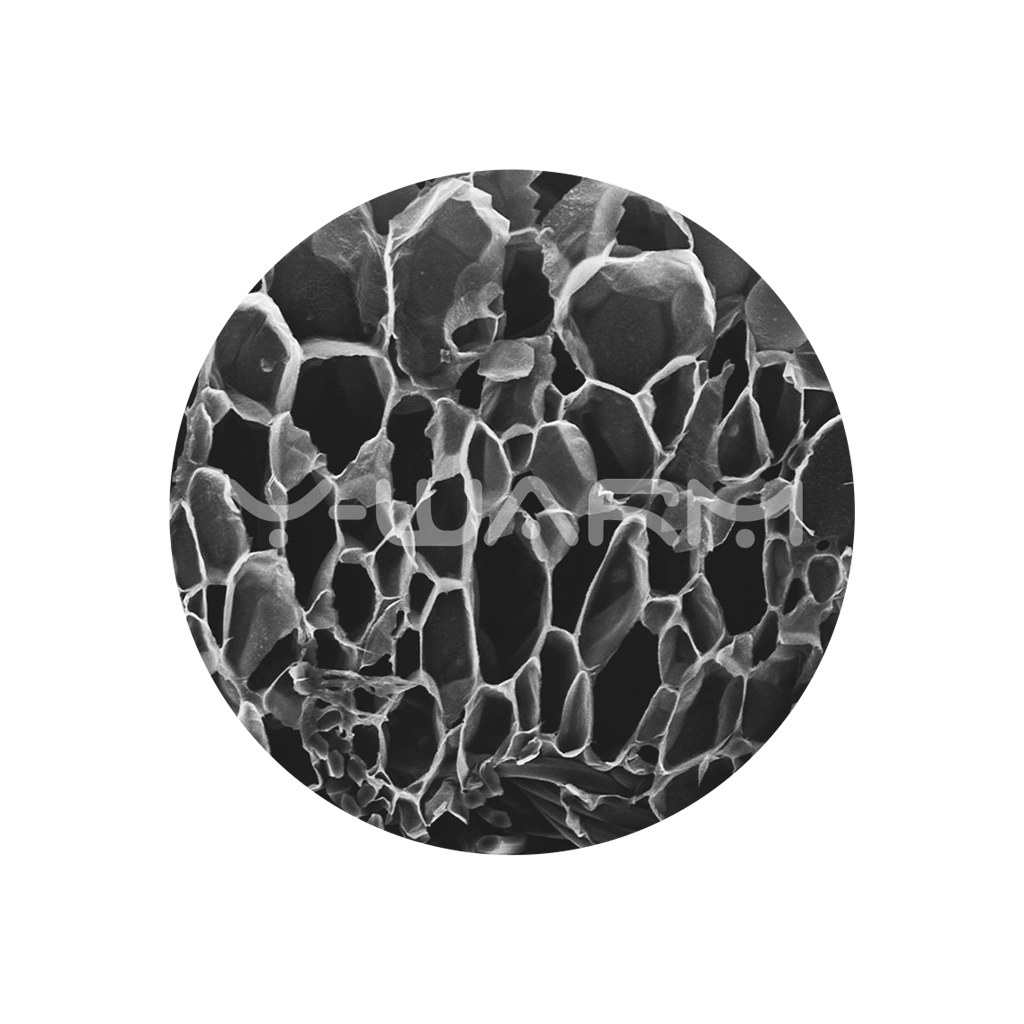

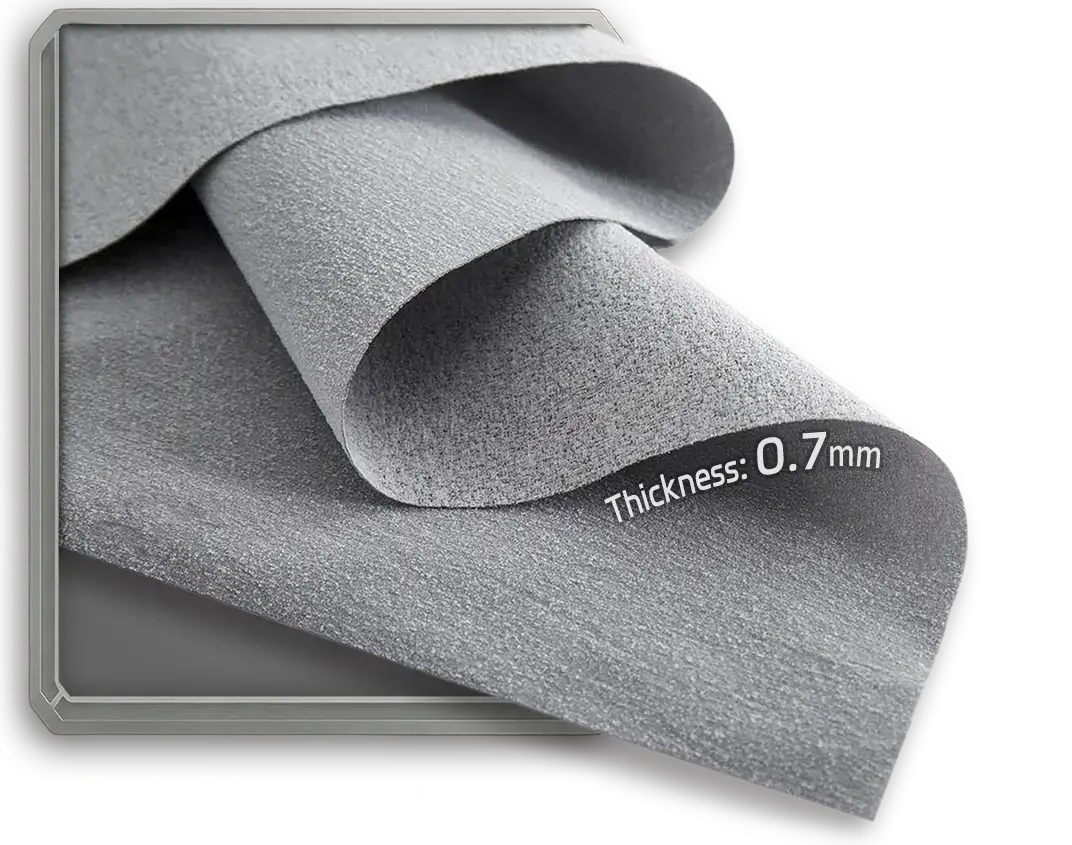

● Dramatic Reduction in Thickness

The first nanoscale “flexible” material with closed-cell structures pioneers the insulation in millimeter-scale.

● Paradigm Shift

The insulation performance which was measured with “loft” is redefined by “thermal conductivity”.

● Comfort Evolution

The combination of the thermal insulation, moisture-permeability, and quick-drying creates a miracle in insulation materials.

0.7mm (Model: YW-01) Increases the product's perceived temperature by approximately 10°C.

For more product models, please refer to “Products and Principles.”

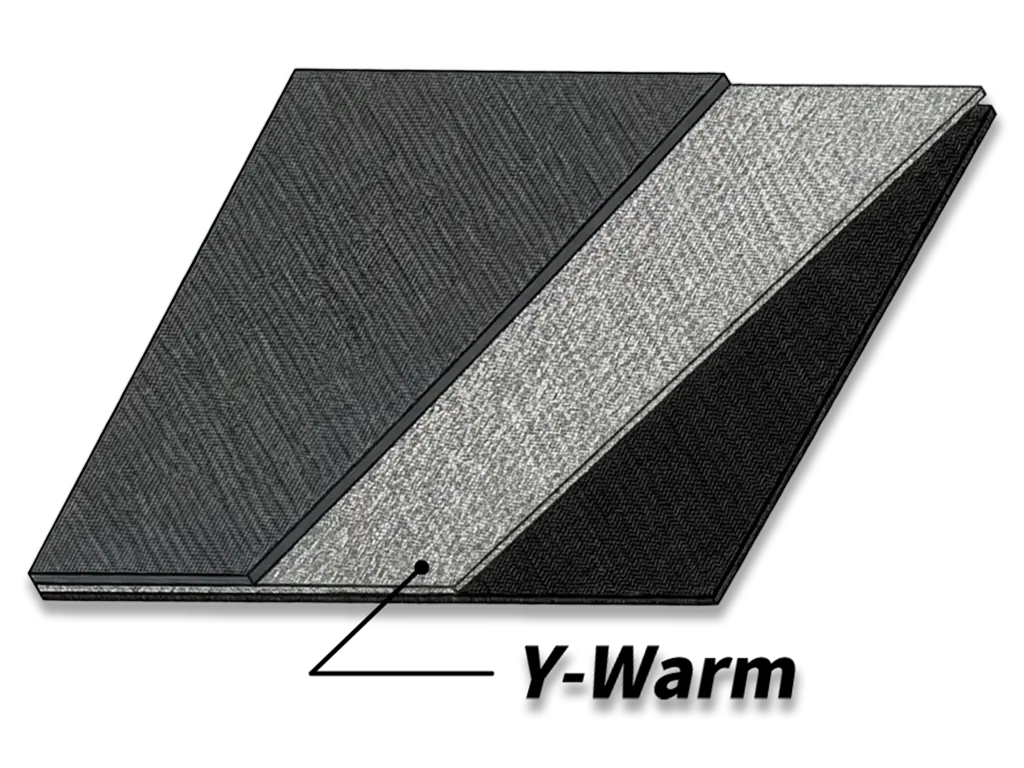

Application Method:

1. Apparel Products: Place Y-Warm on the reverse side of the fabric or other auxiliary materials, then sew it along the edge of the cut piece.

2. Other industries may laminate Y-Warm with other materials as needed.

Application Areas

More industries...

More industries...

Technical overview

Porous material Aerogel shows extremely low thermal conductivity, making it suitable for thermal insulation. However, its defective mechanical properties limit

large-scale use.

After 8 years of dedicated R&D, the Y-Warm team has successfully developed a novel nano-closed-cell flexible insulation material supported by N₂. Its ultra-low thermal conductivity, comparable to aerogel, achieves three global technological firsts.

Laws & Characteristics

Apparel Products

Laminated products