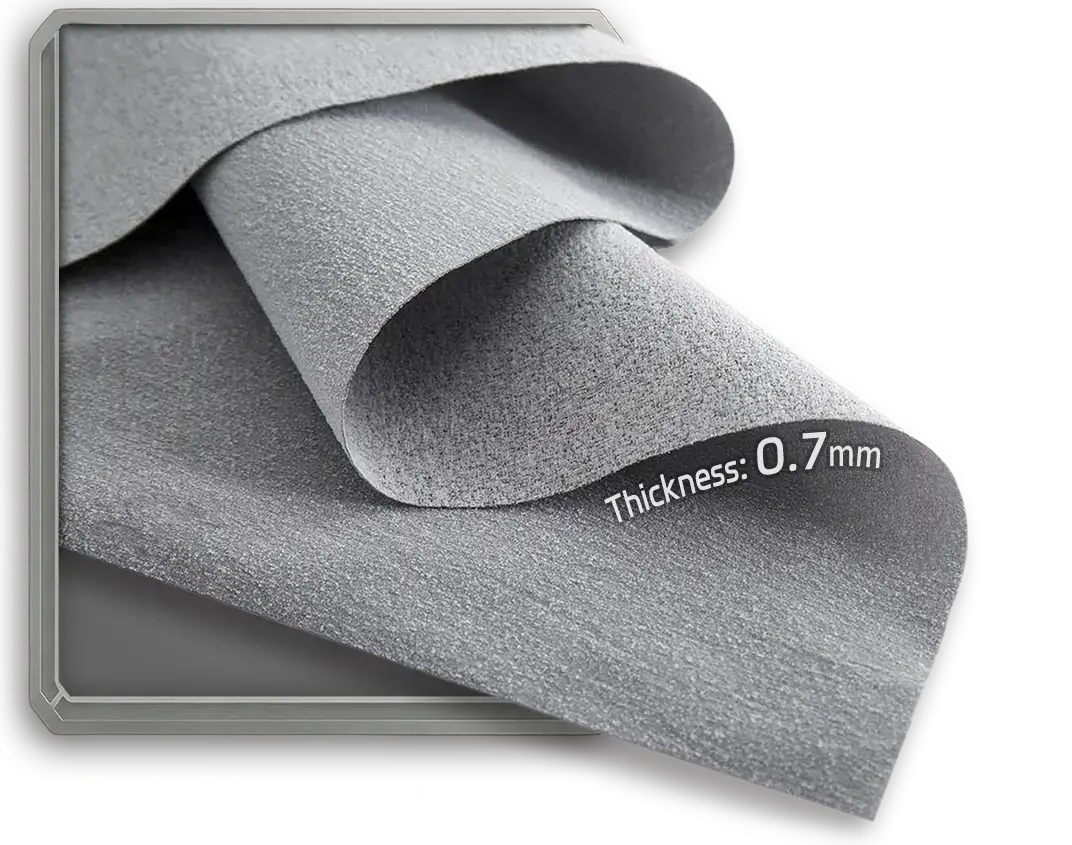

● Dramatic Reduction in Thickness

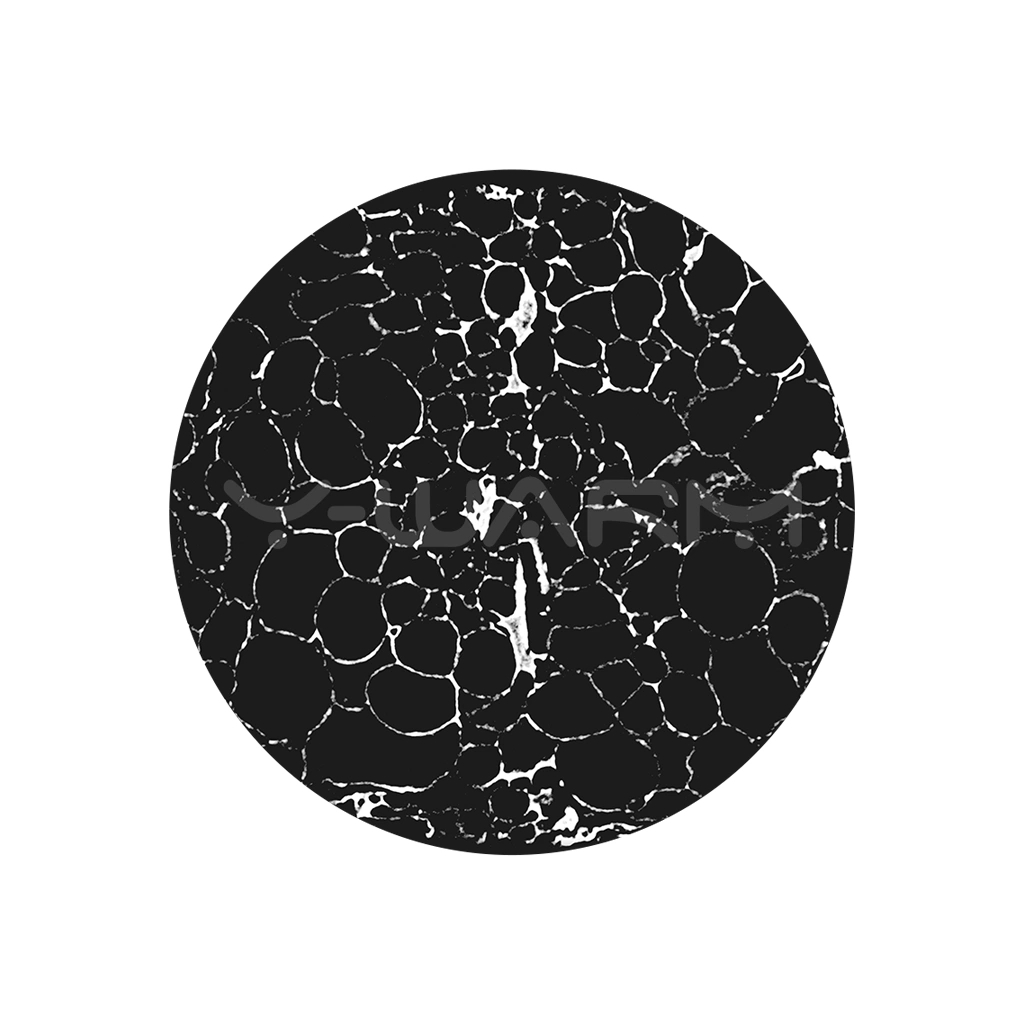

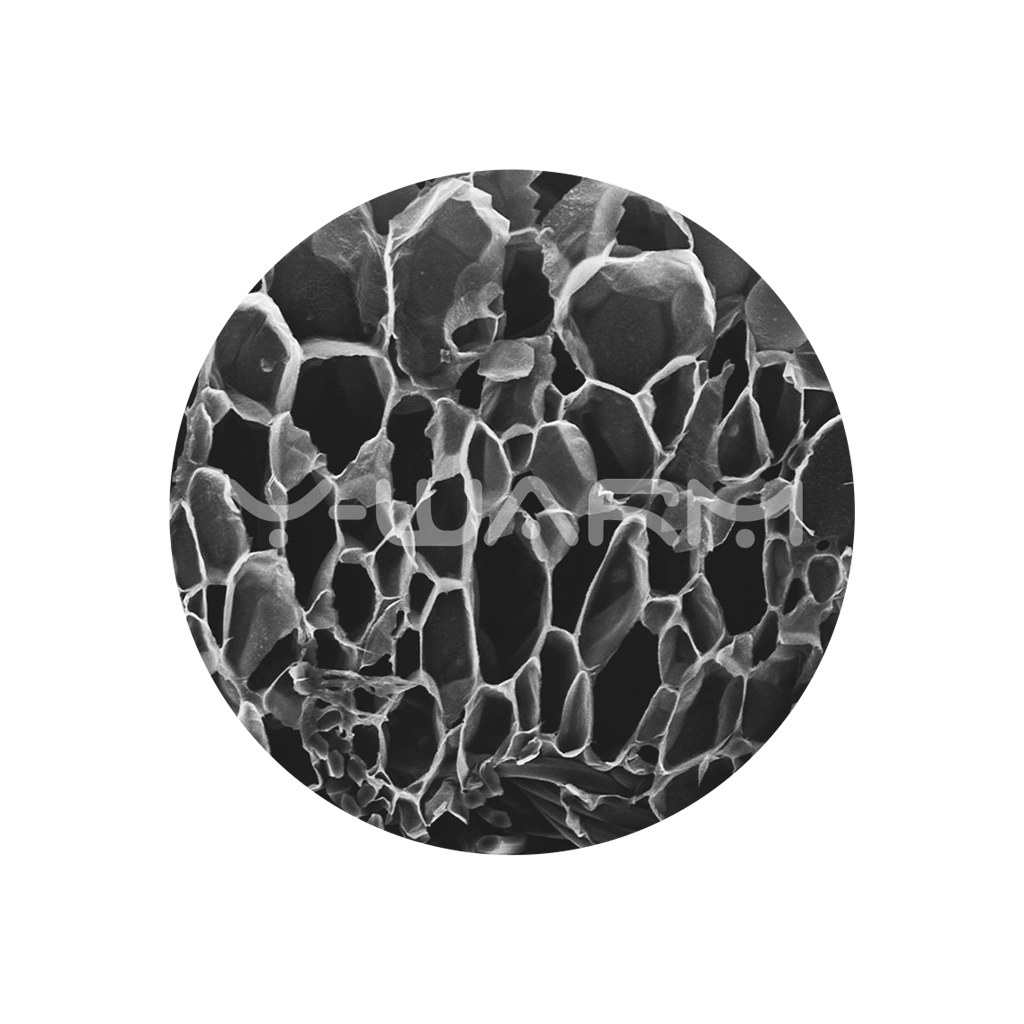

The first nanoscale “flexible” material with closed-cell structures pioneers the insulation in millimeter-scale.

● Paradigm Shift

The insulation performance which was measured with “loft” is redefined by “thermal conductivity”.

● Comfort Evolution

The combination of the thermal insulation, moisture-permeability, and quick-drying creates a miracle in insulation materials.

0.7mm Y-Warm Increases the product's perceived temperature by approximately 10°C.

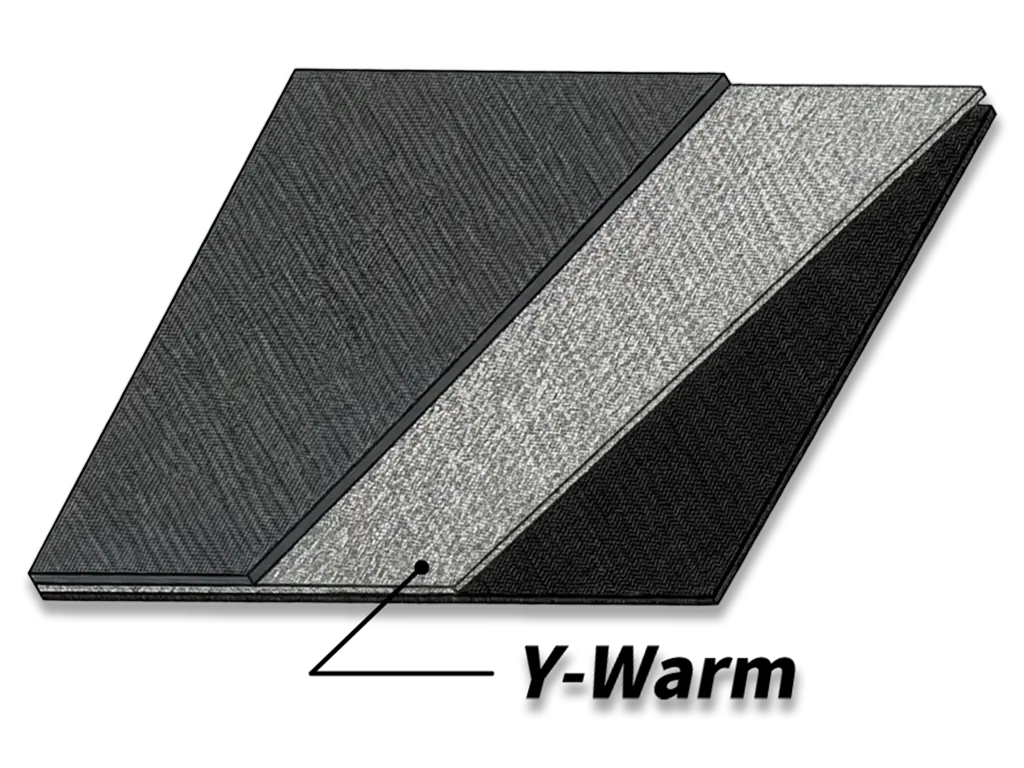

Application Method:

1. Apparel Products: Place Y-Warm on the reverse side of the fabric or other auxiliary materials, then sew it along the edge of the cut piece.

2. Other industries may laminate Y-Warm with other materials as needed.

Technical overview

Porous material Aerogel shows extremely low thermal conductivity, making it suitable for thermal insulation. However, its defective mechanical properties limit

large-scale use.

After 8 years of dedicated R&D, the Y-Warm team has successfully developed a novel nano-closed-cell flexible insulation material supported by N₂. Its ultra-low thermal conductivity, comparable to aerogel, achieves three global technological firsts.

Laws & Characteristics

Apparel Products

Laminated products